Ancient Egyptian metallurgy achieved a major advance with arsenical bronze production on Elephantine Island. There workers alloyed copper using speiss to create tools that cut stone more effectively than pure copper ever could. This process, dated to the Middle Kingdom around 2000 to 1650 BCE, involved heating copper with iron-arsenide speiss in small crucibles, infusing arsenic at levels of 2 to 6 percent for superior hardness. The discovery, led by Jiří Kmošek and Martin Odler, comes from settlement debris in recently excavated houses. They reveal small-scale craft in a Nile border region without large industrial setups. Artifacts such as glassy slags and metal prills confirm deliberate alloying. Hopefully this should shift some views on how Egyptians built monuments with enhanced tool performance.

Elephantine Island’s Role in Advancing Ancient Egyptian Metallurgy

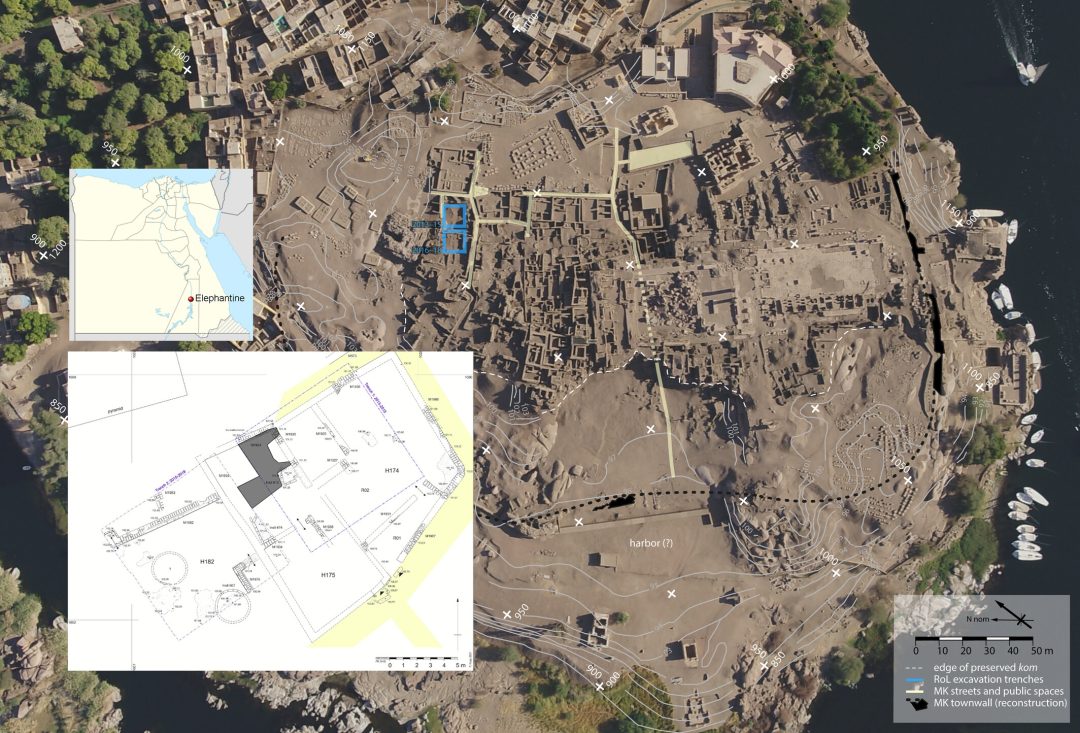

Excavations under the “Realities of Life” project uncovered 850 grams of metalworking fragments across two 10 by 10 meter squares in Elephantine’s northwestern town. Portable X-ray fluorescence scanned nearly 470 samples on-site, identifying arsenic-rich speiss in crucibles that reached temperatures over 1100 degrees Celsius. Scanning electron microscopy in Cairo labs exposed microstructures with corroded iron-arsenide phases and copper droplets embedded in amorphous slag. Workers imported copper and arsenic sources, likely from Nubia or the Eastern Desert, then alloyed them locally in homes to meet daily needs. This decentralized approach explains why no dedicated furnaces appeared, yet high-quality arsenical bronze emerged for chisels and adzes. The find challenges centralized production models, showing border communities innovated metallurgy to boost tool durability against limestone and sandstone.

The Adjective That Defined Superior Alloys

“hsmn”

Further context on ancient Egyptian metallurgy is the knowledge that they had words for alloys bjA and hsmn, which appear in hieroglyphic texts. They describe metals without modern chemical precision. BjA serves as the broad base word for copper, iron, or even alloys, written with Gardiner sign “N34” that depicts a crucible. In contrast hsmn, uses sign “U32” and often acts as an adjective to specify a refined or superior version of bjA. Martin Odler’s conference paper builds on this by challenging the long-held view that hsmn means only “tin bronze,”. A translation set by John Harris in 1961 based on color and artifact ties. Odler points out flaws, such as inconsistent hues in artifacts and hsmn’s links to natron flux for shiny finishes, arguing it covered any effective alloy like the arsenical bronze from Elephantine.

“bjA”

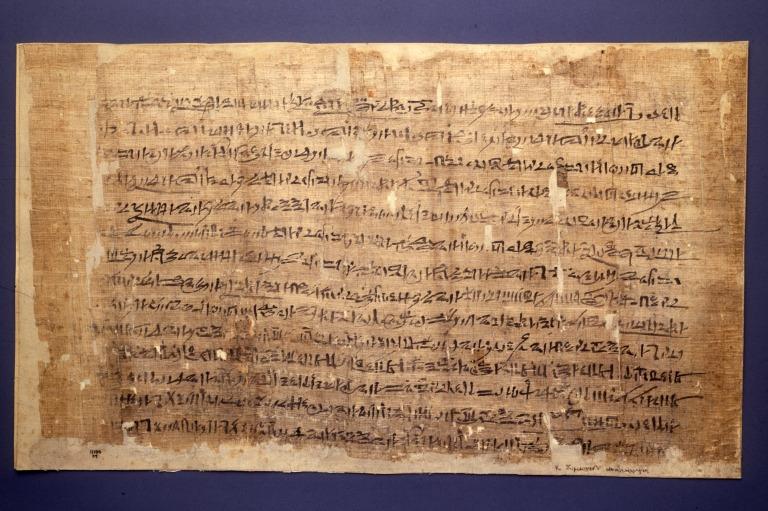

Hieroglyphs clearly separate the terms: N34 for bjA shows a vessel on fire in detailed forms, while U32 for hsmn resembles a goose or curved shape. In faster hieratic script, scribes sometimes simplified both to similar strokes, blending with fire-drill signs for efficiency. Odler revisits texts where hsmn labels mirrors or vessels, not just tools, and notes it evolves across the Bronze Age to describe hardness or polish rather than tin content. This adjective role explains why Elephantine workers produced arsenical bronze, hard and dark. Yet texts might call it hsmn without specifying arsenic. The paper ties physical evidence to language, showing Egyptians prioritized function in naming, which directly supports the speiss cementation process as a deliberate step for better tools.

Papyrus Mayer B: A Window into Hsmn’s Real-World Value

Papyrus Mayer B, a Dynasty 20 record of temple thefts around 1100 BCE, lists hsmn objects like statues and vessels stolen for their melt-down worth, highlighting the metal’s economic pull. Scribes specified “hsmn km” for black bronze, likely arsenical types darkened by iron or sulfur impurities, contrasting lighter tin variants. Odler emphasizes how Mayer B uses hsmn interchangeably with bjA in some entries, supporting his adjective theory and showing thieves targeted high-value alloys. Hieratic writing curves U32 distinctly, aiding quick identification amid lists of gold and silver goods. This document ties directly to Elephantine methods, as arsenical bronze’s dark hue and hardness align with hsmn km descriptions in robbery confessions. Ancient Egyptian metallurgy valued such alloys for prestige items, provoking thoughts on how tool effectiveness extended to sacred crafts.

Copper’s Long Journey Through Egyptian History

Odler’s book “Copper in Ancient Egypt” maps metallurgy from 4000 to 1600 BCE, starting with Naqada native copper and evolving to Old Kingdom smelting in Sinai mines. Pyramid Age workshops at Giza produced arsenical tools with deliberate additions, reaching hardness that pure copper lacked for chiseling massive blocks. Middle Kingdom shifts saw tin imports from the Levant, yet arsenical types dominated locally, as Elephantine proves with speiss cementation. The text details ore sources, crucible designs, and wear patterns, linking bjA to everyday implements while hsmn elevated special ones. This evolution underscores adaptation, where border sites like Elephantine refined imported copper into alloys that sped construction and reduced tool failure.

How Arsenical Bronze Revolutionized Tool Effectiveness

Arsenical bronze hit Mohs hardness around 3, up from pure copper’s 2.5. Allowing chisels to bite into limestone without quick deformation. For granite at Mohs 6 to 7, Egyptians paired bronze with quartz sand abrasives in saws and drills, where alloy strength held grit for grinding. Odler’s EgypToolWear project analyzes edge wear, revealing arsenic enabled cold-hammering to 200 to 300 Vickers hardness, extending chisel life on quarries. Elephantine slags show controlled arsenic infusion via speiss, avoiding brittleness above 8 percent while maximizing cut efficiency.

This effectiveness built obelisks and temples faster, with fewer replacements, fueling Egypt’s architectural dominance.

Stone Tools in the Broader Context of Ancient Egyptian tool Making and Masonry

While arsenical bronze tools is a breakthrough in ancient Egyptian metallurgy. They formed only part of a diverse toolkit for stone carving. Egyptians combined metal alloys with traditional stone implements to handle different rocks and tasks. Flint chisels, made from sharp chert nodules, excelled in the Predynastic and Early Dynastic periods. These tools snapped easily but produced precise cuts through knapping. Diorite chisels and pounders, crafted from hard igneous rock at Mohs 6 to 7, pounded granite and basalt directly. Workers used them to rough out obelisks and statues before finishing.

This mix prevented over-reliance on scarce copper. Bronze chisels handled repetitive strikes on medium stone. Stone tools tackled the toughest without deforming. Elephantine focused on alloy production for daily needs. Broader sites like Giza used all types. The combination sped pyramid construction. It shows pragmatic ancient Egyptian metallurgy. Alloys enhanced, but never replaced, proven stone methods.

Provocative Implications for Egyptian Engineering Feats

The Elephantine breakthrough, paired with Odler’s lexicon and history, dismantles myths of primitive tools or lost technologies in pyramid construction. Arsenical bronze, termed hsmn in texts like Mayer B, provided the edge for precision stonework through smart alloying and abrasion. Egyptians mastered this, adapting to resources and provoking awe at their ingenuity. Future isotope studies may trace speiss origins, but current evidence cements ancient Egyptian metallurgy as a cornerstone of civilization’s wonders.

For more insights on ancient Egyptian techniques read Ancient Egyptian Engineering: From Bedrock to Pyramid Block